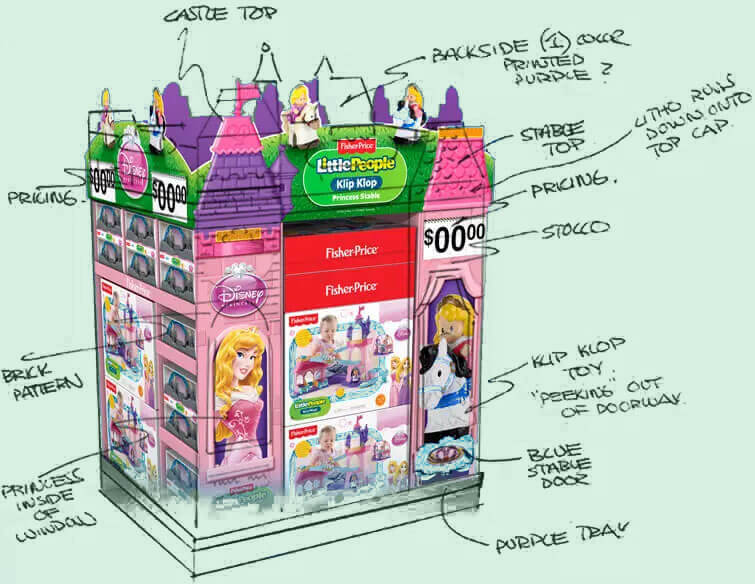

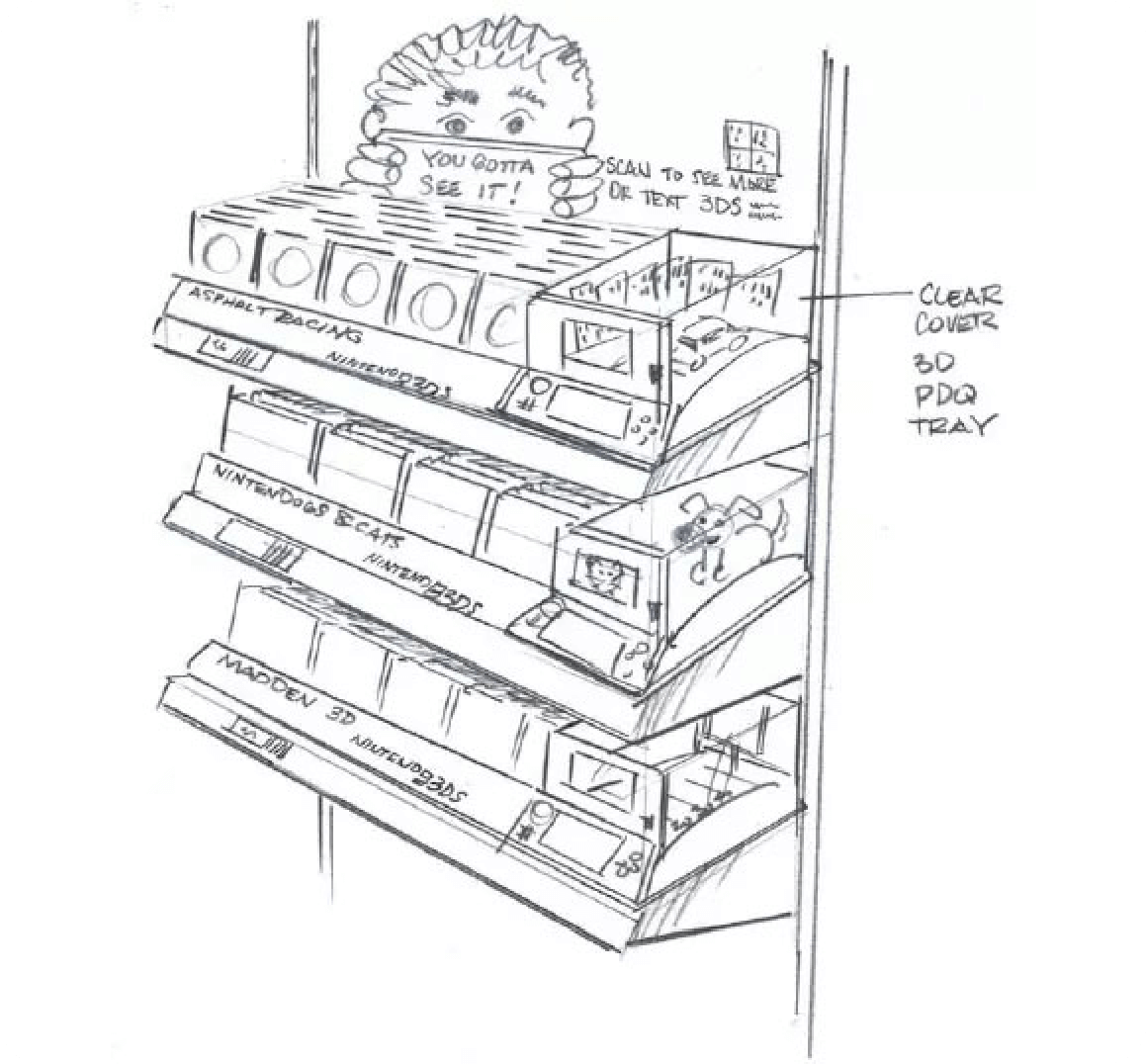

Any custom designed display starts with an idea. From there, our experienced store display designers can take your vision and run with it. Our in-house structural design team brings exceptional expertise and impeccable standards to each project in order to craft unique retail packaging and custom displays. With work that’s regularly featured in some of the biggest retail stores, our team’s reputation speaks for itself. If you want to design a custom display for your products, our talented team provides a creative place to begin.

Our Process

Creative Displays is an industry leader in designing and manufacturing custom retail displays. With over 60 years of experience, they offer a comprehensive process from initial design concepts to distribution. Their in-house printing and centrally located facility in Minneapolis allow for high-quality displays and efficient project timelines, resulting in an on-time percentage of over 99%. Contact Creative Displays to get started on your custom retail display today.

Get Started

5 SIMPLE STEPS:

Design

Prototyping

Printing

Manufacturing

Distribution

Design

Prototyping

Once the concept has been designed, it’s time to begin bringing it to life. We offer visual prototype services that allow clients to see their customized displays before we begin manufacturing. With full-colored and tangible prototypes, you can sign off on every detail of your unique display before finalizing the order. If you need to make any adjustments to your retail store display prototype, just let our team of store display designers know, and we’ll handle your requests promptly.

Printing

Creative Displays Now provides premium custom printing capabilities for a sleek, professional look. Our printing is done in-house so we can maintain control over the project’s timeline and deliver your displays exactly when you need them.

We use advanced printing technology to achieve your desired look and quality. Our capabilities include lithography, flexography and digital printing, and each offers a unique selection of finishes and colors. Our in-house, G7 qualified prepress team leads the industry in color knowledge. The printing stage of our process is particularly important for clients who will be incorporating logos, signature colors and other branding into their custom displays. Precise and vibrant printing will represent the high quality of your products.

Manufacturing

Once all prototypes have been approved and printed, it’s time to manufacture your custom cardboard displays. All manufacturing is done in the United States at our centrally-located facility in Minneapolis, MN. Our machines are built to handle a range of packaging materials, giving us unmatched control over both the cost and timeline of each project. As a result, Creative Displays Now has an on-time percentage of over 99%.

Distribution

To offer the highest quality of service in the business, we take care of your display distribution. During this last stage of the process, our team assembles the displays, packs them by hand and sends them to you by truck or air. With a central location in the Midwest, we’re able to distribute products quickly and efficiently from coast to coast across North America.

Design A Custom Cardboard Display Today

With decades of in-house structural design experience under our belt, Creative Displays Now is here to deliver excellent results for your company. Our team is dedicated to the finest details for the highest quality finished product.

Give us a call at 855-772-1789 to discuss your custom display design ideas and get your project underway. To learn more about pricing, request a free estimate today.