The new Walmart RFID mandate requires more suppliers to use RFID tags on their products. RFID (radio frequency identification) uses radio waves to track products automatically without requiring line-of-sight visibility. The core reasons for RFID retail technology include improving inventory accuracy, reducing out-of-stocks and streamlining supply chains. In 2025, additional categories must be compliant, and all products currently using certain Specs must change to an updated Spec.

This article will guide you through the new requirements.

Walmart’s 2025 RFID Mandate: What’s New?

Suppliers must comply with the latest updates to the Walmart RFID mandate by August 1, 2025, to keep selling in Walmart stores and distribution centers. The expanded use of RFID technology in retail stores is expected to improve inventory management, reduce out-of-stock items and enhance the overall customer experience. An overview of updates includes:

- Expanded scope: The mandate now involves almost all merchandise categories found in Walmart stores, going beyond the initial focus on apparel and electronics.

- Updated specifications: Some of the categories mandated in the past must update their Walmart RFID tags to meet new technical specifications.

- Compliance is key: Suppliers must observe a high compliance rate to avoid penalties.

- Focus on efficiency: Walmart is leveraging RFID to improve inventory visibility, streamline operations and reduce costs.

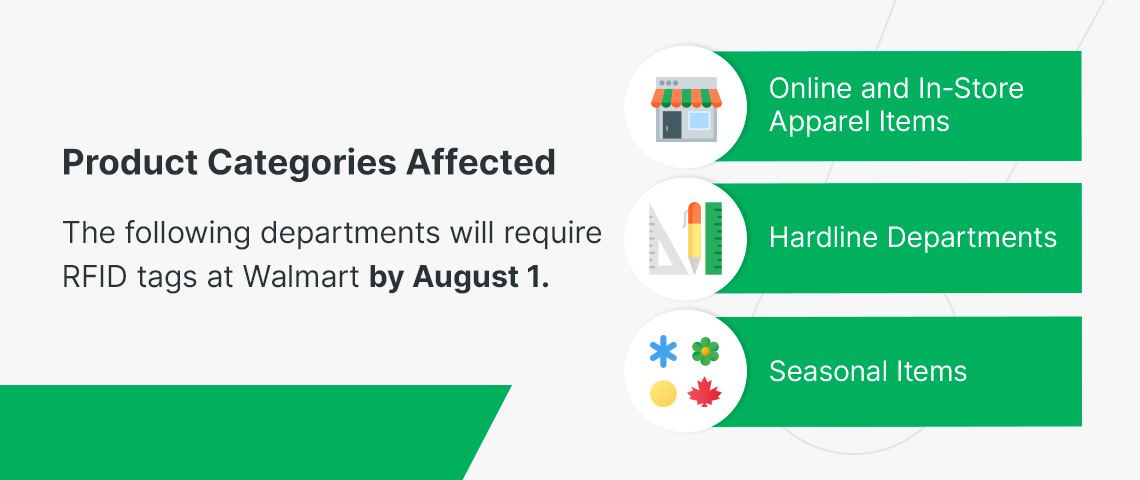

Product Categories Affected

The following departments will require RFID tags at Walmart by August 1.

Online and In-Store Apparel Items

Here are the requirements for apparel items:

- 23-Mens Wear

- 24-Boys Wear

- 25-Footwear

- 26-Infant

- 29-Ladies Sleepwear

- 29-Ladies Socks

- 29-Hosiery

- 30-Bras & Shapewear

- 31-Accessories

- 32-Jewelry & Sunglasses

- 33-Girls Wear

- 34-Misses & Juniors

- 34-Plus Size & Maternity

- 34-Outerwear & Sleepwear

- 41-Team Sports.

Hardline Departments

The mandate also applies to:

- 03-Stationery

- 05-Media & Gaming

- 06-Cameras & Supplies

- 07-Toys

- 09-Sporting Goods

- 10-Automotive

- 11-Hardware

- 12-Paint

- 14-Kitchen & Dining

- 16-Outdoor Living

- 17-Home Décor

- 19-Crafts

- 20-Bath and Shower

- 21-Books

- 22-Bedding

- 42-Automotive (Tires Only)

- 71-Furniture and Luggage

- 72-Electronics

- 74-Closet and Organization

- 87-Wireless.

Seasonal Items

All seasonal program items must also be RFID tagged. Exceptions are Annual Event items.

Out-of-Scope Items

The following items do not have to be RFID tagged:

- Apparel items from online-only brands

- Team sports apparel and sports licensed hardlines “hot-market” Championship products, such as Super Bowl and World Series products

- Items where RFID technology is not compatible, as identified through the Auburn RFID Lab

- Drop ship vendor (DSV) items

- Pay from Scan items

- Third-party Walmart Fulfillment Services (WFS) items

- D18 Seasonal items

- D56 Horticulture items

- D67 Celebration items

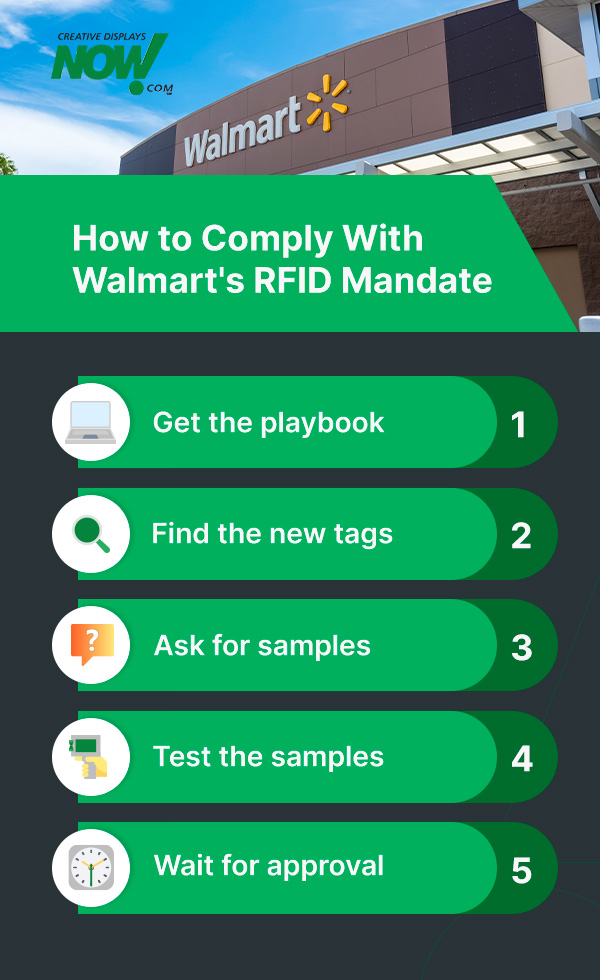

How to Comply With Walmart’s RFID Mandate

There are five steps to follow to comply with Walmart’s RFID requirements:

- Get the playbook: You can find the Walmart RFID playbook on Walmart’s Retail Link (Retail Link > Supplier Academy > Item Setup & Management > Business Specific Resources). Go to the “Inlay Spec” column next to the Department and Category/Subcategory applicable to your product. The reference number will give you the approved inlay list for your product.

- Find the new tags: Using the correct reference number, find the new RFID tags assigned by the Auburn RFID Lab’s ARC Program.

- Ask for samples: Ask an RFID retailer for samples of RFID tags in your approved Spec. You can source customizable sample packs depending on your size requirements and budget. Samples that can be preprinted and encoded to Walmart’s standards will save you time and money when getting them approved.

- Test the samples: Test the printed and encoded RFID tag samples on your product to make sure they fit on all your packaging. The Walmart RFID playbook includes where to put the label, but if your product isn’t covered, use the generic “Tagging Requirements” to find the best place to tag your product. Contact the Auburn RFID Lab for correct placement if you have specialty products with unique packaging.

- Wait for approval: Send your printed and encoded Walmart RFID tags to the Auburn RFID LAB for approval.

The Auburn University RFID Lab database stores the performance and quality data of market-available RFID tags. Inlay manufacturers send new tags to the lab before they’re released to the market. A tag’s performance is measured and compared to all the Specs and added to the approved tag list. Approved inlay lists include inlays — the antenna and microchip mounted on a thin substrate of RFID tags and labels — that have been benchmark tested against existing Specs. Specs are the performance threshold an inlay must meet to ensure a tagged item performs as it should.

In addition to tagging their products, Walmart requires its suppliers to ensure the encoded RFID tag is correct before sending it to Walmart stores. A USB reader or handheld RFID reader can be used for verification.

Understanding Walmart’s RFID Journey

Walmart first started testing RFID technology in the retail industry with select suppliers and products in 2003. Over the years, Walmart expanded RFID use from pallets and cases to individual items. Requiring suppliers to tag their goods with Walmart RFID tags changed how products are supervised from the supply chain to store shelves. More recently, increased visibility of online stock has driven sales and enhanced trust as customers are provided with accurate, real-time updates of stock availability.

Beyond the benefits of supply chain management and online shopping, RFID packaging significantly boosts the efficiency of receiving and processing shipments. Items can be scanned upon arrival, decreasing labor demands and quickly refilling shelves.

Key RFID Milestones

Here are more key dates in Walmart’s RFID adoption:

- 2003: Walmart tells its top 100 suppliers they must tag all cases and pallets with RFID tags within two years.

- 2005: Walmart extends this initiative to all suppliers, though the plan was put on hold by 2007.

- 2010: Walmart begins requiring RFID tags on certain individual items of clothing.

- 2020: RFID tags are rolled out to all apparel products.

- 2022: Walmart expands RFID technology to home, entertainment, toys, sporting goods and several other departments.

- 2024: The mandate extends to cameras and supplies, media and gaming, automotive, crafts, stationery, hardware, paint, and lawn and garden.

- 2025: The largest RFID expansion yet covers even more departments.

How Does RFID Technology Work?

RFID technology is widely used in modern life and has been commercially available since the 1970s. Here’s how it works:

- RFID tags are attached or embedded in an object. They have an antenna and an integrated circuit or “chip,” which stores data. Tags can store more data than a barcode and can even be overwritten with updated information.

- An RFID reader sends out radio waves.

- The RFID tag receives these waves, and the energy is used to activate the chip.

- The tag transmits the data back to the reader and then sends it to a computer system without the reader having to be within line of sight of the tagged object.

Walmart suppliers must use a Gen 2 UF RFID tag with a frequency of 902-928 megahertz.

Implementing RFID in Your Supply Chain

In addition to streamlining things for Walmart, RFID tagging your products will allow you to:

- Track manufacturing processes.

- Manage inventory with improved visibility.

- Verify shipment picking and packing.

- Avoid product theft and loss.

Instead of manually scanning each barcode, you can use a handheld RFID reader to take stock of all your products. This significantly reduces inventory time by reading thousands of tags per second. When stock can be taken daily, more data can be collected, and you no longer need to rely on vague group counts.

Choosing the Right RFID Tag for Inventory Management

Consider these factors when choosing RFID tags:

- Form: Wet inlays, labels and hang tags are used most often in the retail industry.

- Size: Source larger tags for bigger items and smaller tags for smaller items.

- Mounting: Consider the products you’ll be tagging. For example, if you’re tracking jewelry, use a metal-mount tag.

- Attachment: Ensure tags can be removed after purchase. These tags are typically adhesive, string or plastic tag fasteners.

- Range: While Walmart requires an RFID tag read range of at least 20 feet, 3 to 10 feet is adequate in most retail settings.

Benefits of RFID for Walmart and Walmart Suppliers

The expanded use of RFID technology in retail allows item-level intelligence for a wider range of products. Let’s take a closer look at the advantages of RFID for Walmart and Walmart’s suppliers.

Improved Inventory Accuracy

Walmart RFID tags allow for real-time, automated tracking of products at every stage, from manufacturing to the store shelf. Inventory counts become faster and more precise compared to manual or barcode-based systems. Human error, miscounts and lost items are reduced, which means accurate stock levels and quick restocking of merchandise.

Reduced Out-of-Stocks

With better inventory visibility, retailers can quickly identify when products are running low and place orders to suppliers. Automated alerts and data-driven replenishment help keep shelves stocked and minimize lost sales resulting from empty shelves.

Better Supply Chain Visibility

RFID tags provide end-to-end tracking, so suppliers can monitor products as they move through the supply chain. This highlights bottlenecks, delays or misplaced shipments and improves coordination between manufacturers, distributors and retailers.

Faster and More Efficient Receiving

Walmart can scan entire shipments in seconds, reducing time spent on manual checks. This streamlines the receiving process at distribution centers and speeds up product availability. It also reduces labor costs and increases operational efficiency.

Accurate Data for Forecasting and Planning

The technology generates detailed, real-time data on product movement and sales. Businesses can analyze trends, predict demand and optimize production schedules. This supports more accurate sales forecasting and inventory planning.

Stronger Retailer Relationships

Suppliers who comply are less likely to face shipment rejections, penalties or lost business. Trust is built with Walmart, possibly leading to preferred supplier status or expanded business opportunities.

Enhanced Product Security and Loss Prevention

RFID tags can help detect and prevent theft and reduce shrinkage in the supply chain by enabling quick identification of missing or stolen items.

Competitive Advantage

Early compliance with the Walmart RFID mandate allows suppliers to better position themselves to meet future retailer requirements. It can differentiate your business as forward-thinking and technologically advanced and may open doors to new retail partnerships or markets with similar compliance needs.

Improved Customer Experience

Accurate inventory and fewer out-of-stocks mean customers can reliably find the products they want. Faster restocking and fewer errors lead to higher customer satisfaction and loyalty.

How Creative Displays Now! Helps With RFID Integration

For more than 60 years, Creative Displays Now! has specialized in custom retail displays and packaging made from corrugated cardboard, a material that is RFID-friendly and highly recyclable. Our team stays up to date with Walmart’s RFID mandates, and we can design custom RFID packaging solutions that showcase your products.

Seamless RFID Tag Integration Without Sacrificing Branding or Visual Appeal

Creative Displays Now! can incorporate RFID tags into product packaging without interfering with graphics and messaging. Our design process considers the technical requirements of RFID, like tag readability and placement, as well as your brand’s marketing needs, including color, print quality and layout. This means your packaging remains visually impactful and on-brand while being fully compliant with Walmart’s technical requirements.

Guidance on Tag Selection, Placement and Compliance

Our team can give expert advice on which RFID tags are suited to specific product categories, using Walmart and Auburn University’s ARC certification requirements. We can help you decide the optimal placement of RFID tags on packaging to maximize read rates and minimize interference from materials like metal or liquids. Creative Displays Now! can also advise on encoding standards and data requirements, helping suppliers avoid common compliance pitfalls.

Structural Prototypes to Test RFID Performance Before Full Production

Before mass production, Creative Displays Now! offers structural (unprinted) prototypes. These prototypes give you the opportunity to test RFID tag placement and performance in real-world conditions. This ensures tags are readable and compliant before committing to a full production run. Identifying and resolving any technical issues early on reduces the risk of costly rework or shipment delays.

Design, Prototyping, Production and Distribution — All Under One Roof

Creative Displays Now! manages the entire process in-house, from design and prototyping to final production and distribution. This integrated approach streamlines communication, speeds up project timelines and ensures consistent quality and compliance at every stage. Suppliers benefit from a single point of contact and a coordinated team that understands the creative and technical aspects of RFID-compliant packaging solutions.

Preparing for an RFID-Enabled Future

While Walmart’s 2025 RFID mandate is a major shift, the changes will have long-term benefits for Walmart and its suppliers, including better inventory, fewer out-of-stocks and improved supply chain efficiency. Creative Displays Now! is your partner for custom RFID packaging solutions that help you stay ahead and succeed in a changing retail landscape.

We are uniquely positioned to help suppliers navigate Walmart’s RFID requirements by offering custom, visually compelling packaging solutions backed by technical expertise, prototyping capabilities and full-service project management. This makes RFID integration easier, more reliable and more effective for brands selling into Walmart and other major retailers. Contact us today for an estimate or to learn more about RFID-compliant custom retail packaging.

1-866-244-2214

1-866-244-2214